"Cé hé sin" (michael-m-mouse)

"Cé hé sin" (michael-m-mouse)

05/05/2015 at 10:37 • Filed to: Twin clutch, ZF

2

2

1

1

"Cé hé sin" (michael-m-mouse)

"Cé hé sin" (michael-m-mouse)

05/05/2015 at 10:37 • Filed to: Twin clutch, ZF |  2 2

|  1 1 |

!!! UNKNOWN CONTENT TYPE !!!

Why indeed?

We’re most of us familiar with the single clutch gearbox. Push left pedal, move lever, release pedal. Some of us have come across the same idea but automated. Think Smart and heavy trucks.

We may also be familiar with the twin clutch box. One clutch operates on the odd numbered gears and one on the even ones. The box simultaneously engages an even and an odd gear and when a change is required it swaps clutches and then pre engages the next gear that it thinks will be called upon.

But you can have both.

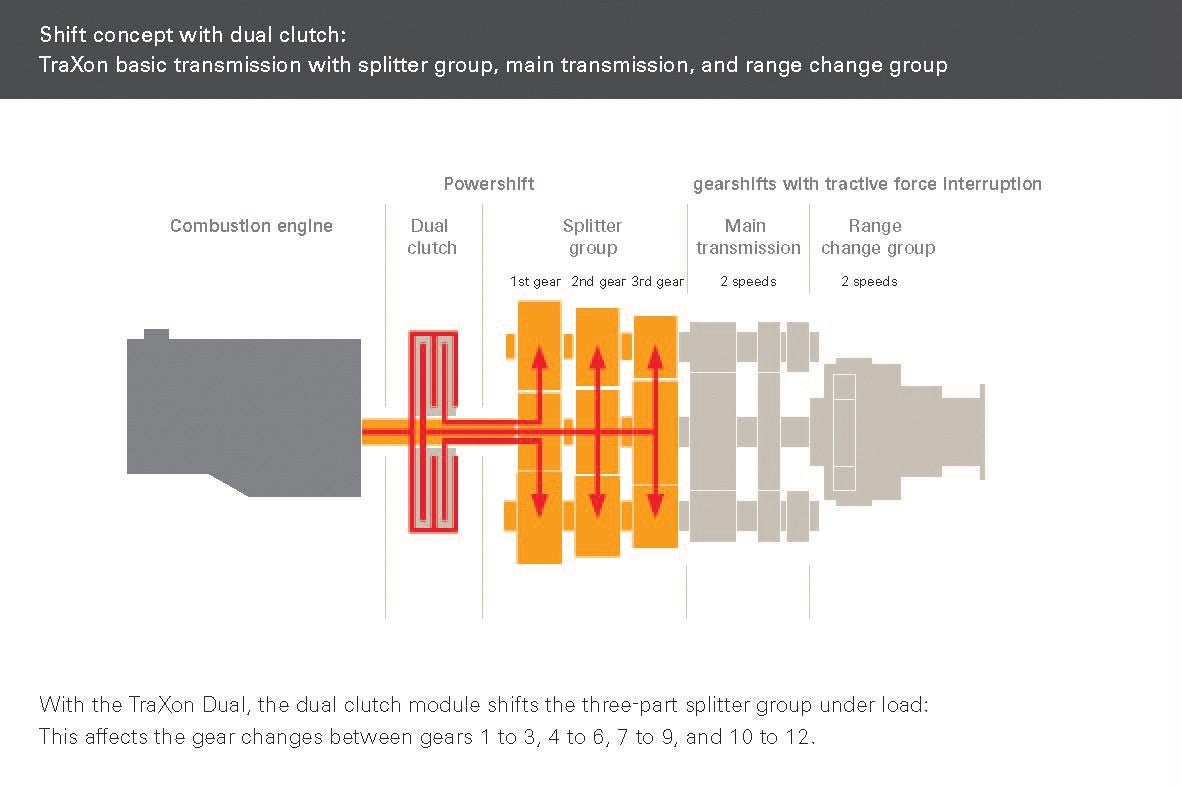

If you have a large truck you have a multiplicity of gearboxes. Obtaining 12 gears involves a two speed, a three speed and a two speed in series. So if we want a twin clutch version of that, we’re going to have difficulties which can be resolved by using twin clutch changes on only one of the boxes and using single clutch changes otherwise.

Here’s a diagram of how that works. The three yellow gears on the left (which are wrongly labelled because second and third are claimed to be driven from the same clutch but never mind) are linked to the two clutches so one operates on gears 1 and 3 and the other on gear 2. Whichever one of these is engaged and clutched therefore operates one of the two gears in the next box in the series which in its turn drives through one of the remaining pair of gears.

So if you go through all the gears the order is:

1-2-3 using the both clutches

single clutch change from 3 to 4 then

4-5-6 using twin clutch

then 6-7 using single clutch

and so on.

So there you have it.

We

can

have both.

Mercedes Streeter

> Cé hé sin

Mercedes Streeter

> Cé hé sin

04/18/2016 at 12:47 |

|

Oh god, I can only imagine how much something like that would cost to fix. :O